The 2.8L Duramax engine is extremely popular. You will find it on Chevrolet Colorado, GMC Savana, GMC Canyon, and Chevrolet Express. Nonetheless, if you are driving one of these Chevvy or GMC models, you might have encountered several issues. And if you have not, you soon might!

Well, just like any other engine out there, the 2.8L Duramax is susceptible to several common problems. But the good news is that most engine problems are easy to take care of. Finding that hard to believe? You should read this guide on 2.8 Duramax Problems entirely!

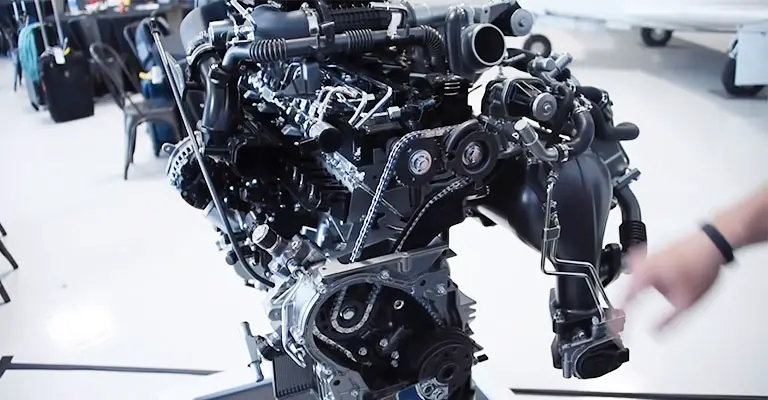

A Little About the 2.8L Duramax Engine

Before we take a deep into talking about the Duramax Diesel 2.8 problems and their respective solutions, we would like to talk a little about the engine. The engine was made available outside North America before it got released there. It made its debut on the international market with the 2012 Chevrolet Colorado.

Nonetheless, there are two different variants of the engine. The first one, the XLD28 Engine, is a four-cylinder turbo 2.8-liter diesel engine. Many will refer to it as 2.8L Turbo Diesel I4 Duramax XLD28. Regardless of what the version is referred to, it first came out through Chevrolet Colorado.

Later, it got integrated into Isuzu KB and Chevrolet Trailblazer. All of which were sold in the international markets. However, this version did not stay in the wild for long. Soon after its release, it was revised to meet North America’s strict emission laws.

The revised version goes as the 2.8L LWN I-4 Duramax turbo-diesel engine. And it debuted in the 2016 Canyon and Colorado. As you might have guessed, these two vehicles were specifically for the North American markets. However, it eventually reached other markets in the United States and Canada.

Common Issues of 2.8L Duramax

With the introduction to the engine out of the way, let us get into the thing that brought you here in the first place. Among all the problems that occur with Duramax 2.8L, failure of the turbocharger, emission system, dead pedal, issues with the timing belt, clogged injectors, and carbon buildup are the most common.

LWN Failed Emission System

To meet the emission laws of North America, General Motors had to make significant changes in the revision. One of the most significant changes was the utilization of a brand new EGR (Exhaust Gas Recirculation) system.

This EGR system lowers exhaust emissions by recycling them and mixing them with the fresh intake air that is headed to the combustion chamber. However, when the system adds cool exhaust gas with fresh air intake, it leads to less efficient combustion.

That eventually causes more fuel to leave the chamber being unburnt and increases the DPM (Diesel Particulate Matter) production. The issue of increased soot production got recognized, and an after-treatment system was added to the equation. It filters the exhaust gas when it is on its way out of the system.

The EGR system also identified the issues regarding the cracked EGR cooler and clogged EGR valve. Nonetheless, with the DPF filter, the issue usually stems from the regen mode.

And the DPF regeneration demands a high level of engine RPM. That will terminate or suspend the process when the operating conditions are substandard.

Afterward, the process will start again during the next ignition cycle. That is if the conditions are right. The ECM will limit the performance of the engine after a couple of failed attempts in the regeneration process.

The Symptoms of Emission System Failure

- Illuminated check engine light

- Reduced engine power

- Rough idle

- Increased engine back pressure

- Increased emission

- Reduced fuel efficiency

- Limp mode

- Knocking noise from the engine

What to Do When You Are Facing Emission System Failure?

It can be pretty annoying to find your emission system malfunctioning. Well, you should know that it can get worse in cold climates and winders. The DEF pump does not really perform that well in such conditions. But the good news is that if you carry out proper engine maintenance, you will not have to worry about this.

Some might suggest you get rid of the after-treatment system as you will not need to worry about it failing when it is not there anymore. But the thing is, this system is incapable of damaging your engine. In the worst case, it will just throw some random error codes and make your engine limp until you take a look into them.

So, your best bet would be to take the car to a professional for a proper checkup. Remember, it is illegal to tamper with the emission control system. You can end up paying a hefty fine if you do so. Therefore, leave it to the hands of the professionals.

Duramax Failed Turbocharger

The 2.8L Duramax boasts a variable geometry turbocharger. It is compact in size, making it spool up exceptionally fast. That eventually allows the engine to output a great level of power.

Nonetheless, the external control module controls the vanes of the turbocharger. The vanes will open up when there is a low engine load. And they will close when there is a requirement for more power.

Although the turbocharger setup is pretty simple, the system is susceptible to catastrophic failures. A lot of customers have complained about the turbocharger failing during freezing temperatures. And most of them are for bet fins.

The Symptoms of Turbocharger Failure

- Damage to the inducer of the compressor wheel

- Loud whine or whistle from the turbo

- Loss of power

- No boost

- Vibration

- Reduced fuel economy

What to Do When You Are Facing Turbocharger Failure Issue?

When you are facing the turbocharger failure issue, you really do not have any other option other than replacing it. But, it is undoubtedly possible to prevent the problem if you frequently replace the cold air intake filter.

Alongside that, consider closely monitoring the engine’s performance, carrying out regular oil changes, and inspecting the turbo during each oil change. Also, consider boost testing the vehicle each time you change the oil.

Dead Pedal

Shortly after the release of the LWN version, there have been many complaints regarding the dead pedal issue. Basically, it occurs when the driver stomps on the accelerator from a relatively slow roll. Most drivers have put out complaints regarding the delay in the throttle response.

Most of those complaints stated that the throttle response took about a second or sometimes more before accelerating. This sluggish response increases the overall risk of an accident when trying to merge right into the traffic. The same thing applies while accelerating during any emergency.

The thing is, the dead pedal feeling is because of the torque management. Basically, the throttle is more responsive when slowly easing on it rather than flooring the pedal. Like any other diesel engine, the Duramax 2.8L is designed for a steady throttle application in order to reduce overall emissions.

For that reason, the fewer the number of changes you put on the throttle settings, the better the engine will behave.

The Symptoms of a Dead Pedal

- Increased engine idling speed

- Vehicle switches to limp mode

- The vehicle does not respond when the pedal is pressed

- An engine warning light comes

What to Do When You Are Facing a Dead Pedal Issue?

There are loads of plug-and-play throttle response systems that can help lower the lag in the throttle response when you try to accelerate. They will generally plug right into the accelerator harness and work like a charm to fix the dead pedal issue.

However, that is not the only option that you have. You can also get a tune, improving the throttle response and removing the torque management.

Duramax I4 Timing Belt Issue

The Duramax 2.8L I4 is a dual overhead camshaft and it drives a timing belt. This timing belt powers the water pump, injector pump, and alternator. Now, General Motors has utilized a timing belt instead of the timing chain because it offers lower noise and has better serviceability.

It has an estimated service interval of 150 thousand miles, which is considerably higher than the timing chain. The thing is, vehicle engineering has advanced a lot since the 80s when the engineers found that the timing belts were not that reliable and experienced unexpected failures from time to time.

The belt, on the other hand, exceeds the replacement interval. However, even if the belt does not show any issues after the 150 thousand miles interval, it is best to get it replaced.

Unlike the Duramax 3.0L, whose timing belt requires a replacement by separating the engine from the transmission, the belt on the 2.8L is at the front. That means there will be no need to separate the engine to access the belt. At most, you might have to work around the radiator fan.

The Symptoms of a Faulty Timing Belt

- Timing belt replacement service warning

- Low oil pressure warning

- Temperature warning

- Overheating engine

What to Do When You Have a Timing Belt Failure?

There is not much that you can do other than replace the belt. And as we have mentioned, as the timing belt of the Duramax 2.8L is on the front of the engine, there will be no need to go through too many hassles when it comes to replacing it.

Clogged Injectors and Carbon Deposit

The direct injection design is the preferred engine design for most vehicles. Why so? Well, such a design improves the engine’s performance. Additionally, this design reduces exhaust emissions and lowers fuel consumption.

However, the design has also introduced some issues that were not that common with port-injected engines. And the issues that we are referring to here are clogged injectors and carbon buildup that is inside the intake manifold.

With direct-injected engines, the deposits that happen due to the exhaust gases gradually settle on the intake valves and port. Also, as the injectors are directly above the engine’s cylinder for better overall fuel injection, they are very much exposed to the intense carbon buildup that can happen during combustion.

This buildup can clog up the nozzles over time. And you can eventually face a lot of issues, such as reduced fuel efficiency and engine misfire.

The Symptoms of Carbon Buildup

- Rough idle

- Check engine light

- Reduced fuel efficiency

- Sluggish acceleration

- Engine misfire

- Heavy exhaust emissions

The Symptoms of Clogged Injectors

- Reduced fuel efficiency

- Engine misfire

- Reduced engine performance

- Crank but no start

- Lean fuel mixture

- Rough idle

What to Do When You Have Clogged Injectors or Carbon Buildup on Duramax 2.8L?

When facing clogged injectors and carbon buildup issues on the Duramax 2.8 Liters, you should consider using fuel additives. They are proven to help prevent these issues. The additives will provide the right level of lubricity to prevent and mitigate carbon buildup on the injector tips.

Furthermore, you can consider installing an oil catch can or making the engine go through an occasional walnut blasting process. These two are highly effective when it comes to taking care of the carbon buildup that happens in the intake manifold.

Final Words

General Motors really offered an engine with impressive quality and design with the Duramax 2.8L. Most of the common problems identified, such as clogged injectors, timing belt issues, and carbon buildup, are either related to direct-injection engines or will not happen when you carry out routine maintenance.

As we discussed the 2.8 Duramax Problems, you now already know how to tackle the issue accordingly. So, if you have a vehicle with this engine or are planning to get one, keep the information in this guide handy, as it will certainly come into use later down the line.

Leave a Reply