Plywood board! There are multiple ways available for you to make your homemade hard tonneau cover, but the most common and effortless process will be making it with a plywood board. As in this can be found easily with sizes and shapes.

How to Make a DIY Hard Tonneau Cover

The very common way to create a bed cover for your truck is to go for a cardboard material. You’ll easily be able to manage that in any kind of large shape. Moreover plywood and wood categorized board are also flexible for modeling as per your bed size.

Procedure

Firstly choose a fine piece of cover material that can be plywood or aluminum or any material you find easy to reshape or fits your bed. If it’s not aligning with your truck bed, try remodeling. Else the raindrops and other things will keep on being dumped in the bed.

The next most vital part is to bind the board appropriately. A common way for binding is using gorilla tape, it’s removable and also sticky enough to hold things in space. The binds will lessen the slippery moves and will stick.

Portioning

You can simply use the whole board as one or you might make segments for working facilities. In this case, you can use hinges, to make a portion in the huge board. The rectangular hinges are affordable and flexible. They can move the cut parts in a half-circle.

What if you don’t want to have partitions? That’s also fine, but the problem is you’ll have to deal with a whole board every time. Again you’ll have to face problems where to keep the board. Might not get to cover the bed always, so you see there are limitations.

Anti-slip covers

Your bare plywood’s surface is technically unstable. So you might find something that is matte and waterproof and consequently, it doesn’t affect the bed with pollutants and also the cover lasts for long.

How to Make a Homemade Aluminum Tonneau Cover?

So a homemade aluminum bed cover is not a go-to go trial. For having an aluminum one, you’ll have to have multiple pieces of equipment to adjust the edge cuts and borders for bed rails and shaping the metal sheet.

The process of boarding the cover is similar to any common ways, but the special facility it can ensure is to give an all-weather compatibility assurance. And also it will last longer efficiently. Not only the longevity and buoyancy but also gives a smarter look to your truck.

Here’s a seemingly perfect procedural video for you to understand how you can exactly create your aluminum bed cover with the necessary tools and supports.

DIY Hard Roll-up Tonneau Cover

Well when you’re purchasing the covers available in the market, they are either tri-folds, else roll-ups. But technically when you’re making things DIY you need at least a minimal outcome from your custom work.

The preference is you don’t stick to something that just a cover of a board, rather make it fold. The roll-ups that we find in stores have multiple supported segments that are tough to build in the DIY process, which might be a time-consuming thing. At least make one fold, for a better experience in DIY cover.

Part the cover board and join them with hinges that can fold up to 100%. You’ll have to make holes in the board so that you can fit the joining screws. Also, you need to make the partitions in a calculative manner as in you’ve got the clamp systems to have a proper alignment with the board.

DIY Retractable Truck Bed Cover

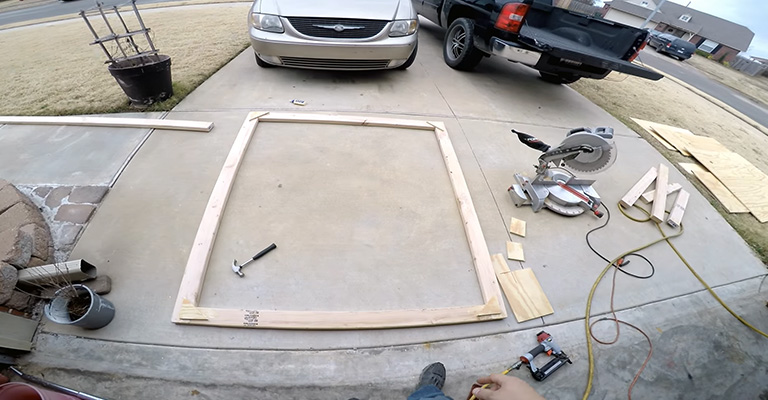

Retractable bed covers are manually created with piano hinges to make the cover a folding one. You’ll need, 1×2” plywood or aluminum, 2 sheets, glues, screws, and other saw type equipment according to board material.

It’s a time-consuming process and effortful work, yet worth trying. Retractable bed covers are smart in look and user-friendly.

How to Build a Truck Bed Cover With Plywood?

A very basic way of making a bed cover is using plywood. The procedure is depicted in the following segments.

Measure Accurately

Firstly make sure the measurement is accurate. Usually, the sheet sizes are 2×4 but you might need to reshape according to your cab, tailgate, and bed rails.

Set It Up

Then assemble the supports, sheets and join with hinges, tape the joints with gorilla tapes or any other sustainable binders. Give some waterproof color coat to have a nicer look

These are the very basic work. But the toughest and sensitive part is to take the proper measurements. The following site might help you with the idea.

DIY Tonneau Cover With Toolbox

This is a great process to get a perfect tonneau cover, because in the toolbox you have a header box, necessary clamps, nuts, and bolts, tighten tools, saws, and other supportive rails with piano hinges.

A full compact tool guide makes your work easier than ever. Check out the video below for a viable interpretation.

FYI

Is a DIY tonneau cover better than the market ones?

This is all up to your preference. If you have a good idea about the price range of tonneau covers then you must know that tonneau covers cost a handsome amount of money. You also might get confused with multiple brands.

DIY is customized by you so you know the best of it and your truck. Still often it’s not easier to just go and create your own, so the store ones are smart and life savior.

Conclusion

DIY is always fun and customizing your tools and the working arena is so hyped. But making a DIY hard tonneau cover is not always a cupcake. Yet it’s a satisfactory procedure. If you are not familiarized with tool works, you might find it hard to have a DIY tonneau cover, so you might switch to the market available ones.

Leave a Reply