If you have ever worked with the internal parts of a vehicle, the harmonic balancer might seem familiar to you. But most vehicle owners are unaware of this device and wonder about what is a harmonic balancer and why we need it in a vehicle.

Basically, a harmonic balancer is an integral part of the combustion engine, which mainly absorbs the vibration of the crankshaft. It is often called a harmonic damper though there is a slight difference between them.

In this article, we have tried to cover all the related information about a harmonic balancer that can be a summed-up guideline for you. So, let us just dive into this!

How Does A Harmonic Balancer Work?

Looked into the internal parts of your vehicle engine and noticed how the engine actually works? When the engine is initiated with a starter, it acts as a rotational system which also includes the circulatory movement of the crankshaft.

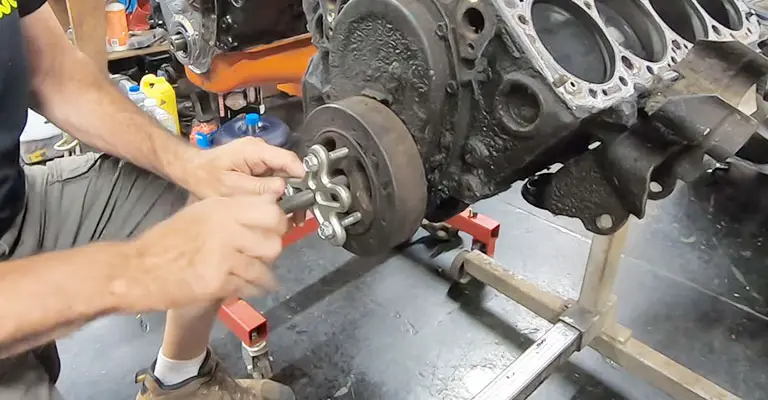

A harmonic balancer is made of metal and rubber, which remains mounted on one end of the crankshaft of the combustion engine. It consists of three parts: the inner part, the rubber-made insulator, and the fan belt.

Due to the continuous movement of the crankshaft and other parts associated with the combustion engine, it produces shuddering and vibrations. These vibrations can be too intense to handle for the vehicle engine.

Here in this stage, a vehicle needs a harmonic balancer to handle these vibrations. So, how does a harmonic balancer work?

Basically, a harmonic balancer acts as a counter to all types of vibrations associated with the vehicle engine. As an engine produces a large amount of power, it leads the engine parts to move continuously at high speed, creating intense vibrations.

A harmonic balancer is attached to the crankshaft in a well-fitted way so that it can move in the same step as the shaft. As a result, there remains no obstruction between the crankshaft and the combustion engine, and it can absorb the vibrations efficiently.

Why Do You Need A Harmonic Balancer?

The main job of a harmonic balancer is to protect the crankshaft and the combustion engine from heavy shuddering and intense vibrations.

Often people think that a harmonic balancer would be useless if the vehicle runs at a lower RPM. But this is not a valid concept to oppose the installation of a harmonic balancer because it can lead to a failed combustion engine due to internal vibrations.

Whether your vehicle runs at a high or low RPM, vibrations are meant to be produced after you initiate your vehicle engine. Without a harmonic balancer, the crankshaft remains at a huge risk of getting broken and damaged.

That might be your worst nightmare, as the whole regulatory system of the engine might fail at that point. A harmonic balancer is a savior for your engine, maintaining your vehicle’s optimum performance.

The harmonic balancer is often called a harmonic damper as it dampens the parts associated with the engine. But the balancer is a bit different from the damper because of having an extra counterweight which helps to balance the rotating assembly.

What Are The Symptoms of Bad Harmonic Balancer

A harmonic balancer can become partially inactive after a certain period, which can affect the engine’s overall performance. If you are aware of the symptoms of a bad harmonic balancer, you can be prepared for any malfunctions and act accordingly.

Here, the most common symptoms of a bad harmonic balancer are discussed briefly for your convenience.

Physical Damage

The physical damage of a harmonic balancer is the most common symptom that you can easily notice. This includes worn-out metal parts, missing rubber insulators, or any damage to the fan belt.

Separating Parts

If you notice that the parts of the harmonic balancer are separated due to engine pressure, there is a chance that the balancer is not working properly. Generally, the outer ring and hub can be separated in case of extreme vibrations in the engine.

Wobbles of the Balancer

Basically, harmonic balancer wobbles include the deterioration of the rubber-made part which is attached to the crankshaft. It affects the rotation of the balancer with the crankshaft and might be a cause for failure.

Loosen Bolts

A few connecting bolts and nuts attach the harmonic balancer to the crankshaft of the vehicle engine. A bad harmonic balancer might contain loosened or broken bolts that can detach it from the crankshaft with the slightest vibration.

Worn Out Bearings

After a certain time, the bearings of the balancer can get worn out and damaged. If you notice that the bearings are worn out, there is a possibility that the balancer is going to degrade very soon.

Failure of a Harmonic Balancer

Any defect in the harmonic balancer can cause severe malfunction to the entire combustion engine along with the other associated parts. Have you ever thought of what happens when a harmonic balancer fails, and what are the reasons behind this?

There are a bunch of reasons why your harmonic balancer can experience failure. Generally, the failure can be of two types: physical and mechanical. If you notice any issues with the balancer, these are the possible reasons that might be the culprit behind the failure.

Excessive Vibrations

As we know, the harmonic balancer is designed to absorb the vibration generated by the combustion engine. But if the vibration becomes too intense, the harmonic balancer often cannot take this excessive load and fails.

When the cylinder fires, the combustion engine generates vibrations at certain frequencies. Along with the vibrations, a relative force acts on the crankshaft. To prevent any damage to the crankshaft, the harmonic balancer works to counter that vibration.

In case the frequency of the vibrations exceeds the usual level, the harmonic balancer finds it tough to handle the force, and eventually, a failure occurs.

Worn Out Rubber Layer

The rubber layer of the harmonic balancer is the most efficient part of the whole construction, absorbing the generated vibrations. Generally, the metal part is attached to the crankshaft through the rubber layer and fan belt. In case the rubber layer is worn out or damaged, the whole system might get interrupted.

As the harmonic balancer keeps moving back and forth continued with the crankshaft, the working capability might decrease after a certain period. It can lead to wear and tear of the associated parts, including the metal and rubber layers.

If the rubber layer of the harmonic balancer wears out, it can’t absorb the engine vibrations effectively. So, you should always check the rubber layer and replace it when necessary.

Broken Crankshaft

When the crankshaft itself breaks down due to excessive pressure on the engine, you might experience the failure of the harmonic balancer.

The crankshaft is directly attached to the combustion engine of a vehicle by connecting nuts and bolts. If the bolts are too tightened, they can break and generate cracks in the crankshaft. Eventually, these cracks become larger, and the crankshaft can break anytime in such a situation.

If you notice any cracks in the crankshaft, replace it immediately with the help of a professional. Otherwise, the harmonic balancer might fail suddenly due to the broken crankshaft.

Overheating of the Engine

An overheated engine might affect the overall mechanism of a harmonic balancer due to the generated pressure. So, if your vehicle is overheating continuously, it can be the main culprit behind the failure of the harmonic balancer.

When an engine produces excessive heat, and it becomes almost impossible to reduce the temperature, it generates a high pressure on the crankshaft and also affects the harmonic balancer.

In such a situation, the balancer might shut down and stop working if it can’t endure this extra pressure. So, you should check if the coolant and temperature sensors are working properly or not because they help to reduce engine heat which can eventually prevent the failure of the harmonic balancer.

Frequently Asked Questions

- How to check the harmonic balancer?

First, start your vehicle’s engine to check whether the harmonic balancer wobbles or not. Take a close look at the balancer and notice if it goes back and forth while rotating around. If you see it wobble, surely, the harmonic balancer is having issues, and you should take your vehicle to a mechanic for further inspection.

- Where to find the harmonic balancer in your car?

Generally, you can find the harmonic balancer of your car attached to the crankshaft. The middle part of the harmonic balancer is the hub which acts as a connector between the crankshaft and the balancer.

- Is it safe to drive with a wobbling harmonic balancer?

Actually, you should not drive your vehicle if the harmonic balancer is wobbling because a wobbling balancer indicates several malfunctions that can lead to the failure of the engine and other associated parts.

Final Words

A harmonic balancer is an ultimate savior for your vehicle to protect it from unwanted vibrations caused by high frequencies. Hopefully, this article is your complete guideline to know what is a harmonic balancer and how it works to save your engine from enormous damage.

Leave a Reply